【導(dǎo)讀】工業(yè)生產(chǎn)正進入一個新的時代,即大規(guī)模的自動化生產(chǎn)取代人類手工勞動的時代,這種趨勢在世界其他地方出現(xiàn),但是最有可能在中國取得最大的發(fā)展,電子元件網(wǎng)推出IMS對此專業(yè)分析文章的中文版,以幫助大家了解。

工業(yè)機器人年復(fù)合增長率

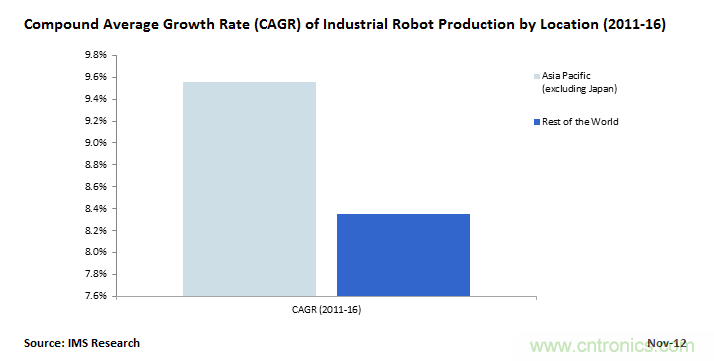

2012年全球生產(chǎn)了二十萬左右的工業(yè)機器人,生產(chǎn)這些機器人的廠家主要在歐洲和日本,這些地區(qū)已經(jīng)具備建立起工業(yè)機器人生產(chǎn)的基礎(chǔ)。在2011-2016年之間,機器人產(chǎn)品在亞太地區(qū)(包括日本)預(yù)計有9.6%的年復(fù)合增長率(CAGR),高于世界其他地區(qū),中國對這個增長有顯著貢獻,而諸多影響因素可能使這個增長率增加的幾率很大。

從那家供應(yīng)商購買機器人取決于許多因素,類似于成本,應(yīng)用,地點以及專業(yè)因素。某些情況下,政治因素也會有影響。比如,中國的終端用戶反感同日本供應(yīng)商進行生意往來,因為他們各自的政府在釣魚島問題上的爭議,而大量應(yīng)用于制造業(yè)基礎(chǔ)投資的資金來自于中國政府控制的基金。

中國工業(yè)產(chǎn)品復(fù)合增長率比過去十年大概增加了14.5%,從而產(chǎn)生對于自動化的配套要求。在中國最近公布的第十二個五年計劃中,明確表示:相對于嚴重依賴進口的方式,國家將會優(yōu)先選擇國內(nèi)供應(yīng)商提供的原料產(chǎn)品。本地制造商類似于GSK和SIASUN。盡管國內(nèi)制造商尚需一段時間達到產(chǎn)品的可靠性要求,而主要的機器人生產(chǎn)商,ABB,KUKA和Yaskawa已經(jīng)在該地區(qū)建立了生產(chǎn)基地。

可證實新聞是:中國工業(yè)機器人新聞是富士康宣布未來2-3年投入100萬機器人到其工廠中,并且銷售工業(yè)機器人。這個消息雖被質(zhì)疑,但他們的確有投資自動化產(chǎn)業(yè)的需求,這來自于日益增長的關(guān)于富士康雇員的待遇和用工環(huán)境問題。且不論富士康是否能達成這個雄心勃勃的目標,在中國,對于工業(yè)機器人的關(guān)注增長是毋庸置疑的,隨著中國社會人口結(jié)構(gòu)變化,企業(yè)發(fā)現(xiàn)越來越難于發(fā)現(xiàn)廉價勞動力,因為很多年輕人相對于學徒型職業(yè)發(fā)展道路,更熱衷于提高自己的教育水平。隨著中國出現(xiàn)更多的本地機器人制造企業(yè),更成熟的型號名稱,可以清楚的看到,在未來十年中,中國機器人工業(yè)生產(chǎn)將會比世界上其他國家增長更快。

電子元件技術(shù)網(wǎng)翻譯原創(chuàng),原文請參考第二頁

[page]

The Growth of China’s Industrial Robot Production

Kiran Patel

There were an estimated 200,000 industrial robots produced worldwide in 2012. The majority of the manufacturing of these robots took place in Europe and Japan, where there is already a base of established industrial robot producers. Between 2011 and 2016, the production of industrial robots in Asia Pacific (excluding Japan) is forecast to grow at a CAGR (compound average growth rate) of 9.6%, more than any other region in the world, with China set to contribute significantly to this growth. There are numerous influencing factors which may cause this CAGR to further increase by a large factor.

The decision to buy a robot from one vendor over another is dependent on many things such as cost, application, location and range of expertise. In certain circumstances, political alignment may also play a part. For example, Chinese end-users may be reluctant to do business with Japanese vendors due to the dispute between their respective governments over the Senkakus-Diaoyus islands - a significant amount of investment into manufacturing infrastructure relies on Chinese Government funding.

Chinese industrial production has increased at a CAGR of approximately 14.5% over the past decade, and the country’s demand for automation has followed suit. In its recently announced 12th five-year plan, it was clear that the country will seek to source goods from domestic suppliers rather than rely heavily on foreign imports. Local manufacturers such as GSK and SIASUN are two examples of domestic suppliers. However, it may take some time for domestic producers to establish credibility (even with a low cost solution), especially since major robot manufacturers such as ABB, KUKA Roboter and Yaskawa have opened up manufacturing facilities in the region.

Arguably the biggest news concerning the industrial robot market in China has been the announcement of Foxconn’s intention to deploy one million robots in its factories in the next 2-3 years, with intentions to sell onto the open market as well. This news has generally been met with scepticism. However, there is a definite need for the business to invest in automation, with growing concerns regarding the treatment and working conditions of its employees.

Whether or not Foxconn meet their ambitious production target, there is little doubt that the interest in industrial robots is growing in China. As the social demographic changes in China, businesses are finding it more and more difficult to find low-cost labourers as more young people are furthering their education rather than taking vocational apprenticeships. As more local robot manufacturers appear in China, alongside some of the more established names, it is clear that industrial robot production is set to increase more than in any other country in the world over the next decade.